CNC lathes and CNC Swiss machines are two distinct types of computer numerical controlled machines used for various manufacturing processes. Although they share many similarities, their differences can have a significant impact on the end product. In this section, we will explore the main differences between these two types of machines, focusing on their key features, functions, and applications. By understanding the unique characteristics of each machine, manufacturers can make informed decisions when deciding which machine to use for specific projects.

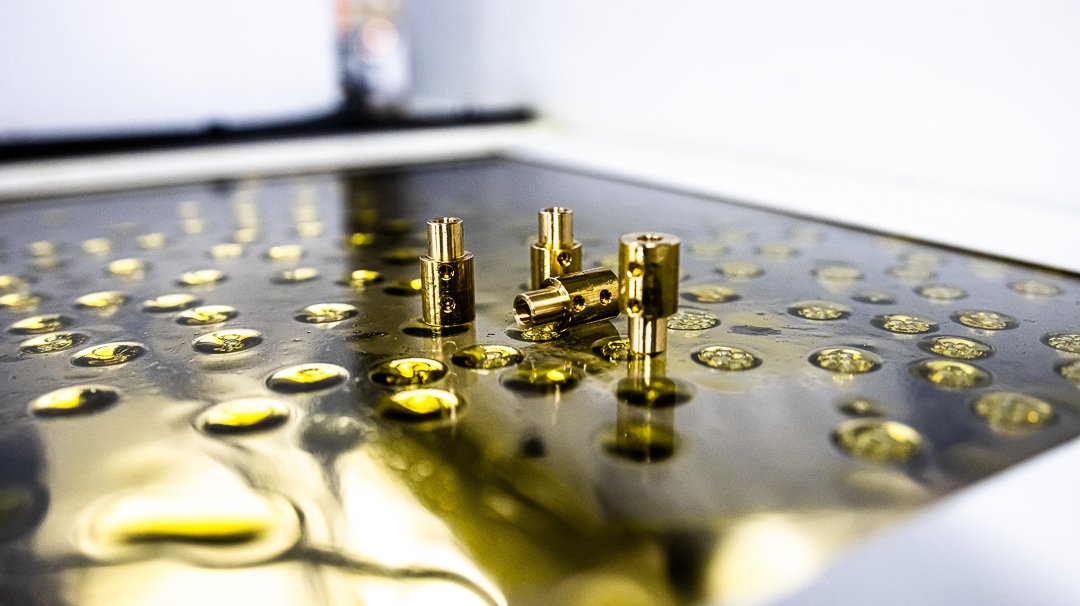

While both CNC lathes and CNC Swiss machines are types of CNC machining tools, they have several key differences in terms of design and intended use. For example, CNC lathes are designed to handle larger parts that require cylindrical turning, while CNC Swiss machines are typically used for making smaller and more complex parts with tighter tolerances.

“CNC Swiss machines offer their ability to quickly produce high-precision parts in large quantities, which can help businesses streamline their manufacturing processes and improve overall efficiency.”

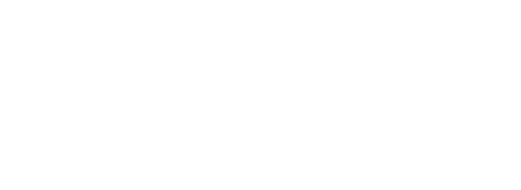

One of the main differences between CNC lathes and CNC Swiss machines is the way they hold and rotate the workpiece. CNC lathes hold the workpiece in a chuck and rotate it while the cutting tool moves along the length of the part.

CNC Swiss machines, on the other hand, clamp the workpiece in a guide bushing and rotate it while the cutting tool moves back and forth along the length of the part. This difference in design allows CNC Swiss machines to produce more precise and complex parts than CNC lathes, making them ideal for industries such as medical and aerospace manufacturing.

Additionally, CNC Swiss machines have a sliding headstock design that enables machining on the same side as the guide bushing, providing better precision and stability for the manufacturing process.

“Overall, understanding the differences between CNC lathes and CNC Swiss machines can help businesses choose the best tool for the job and achieve optimal results.”