Multi Spindle Screw Machining Services

What is a Multi Spindle Screw Machine?

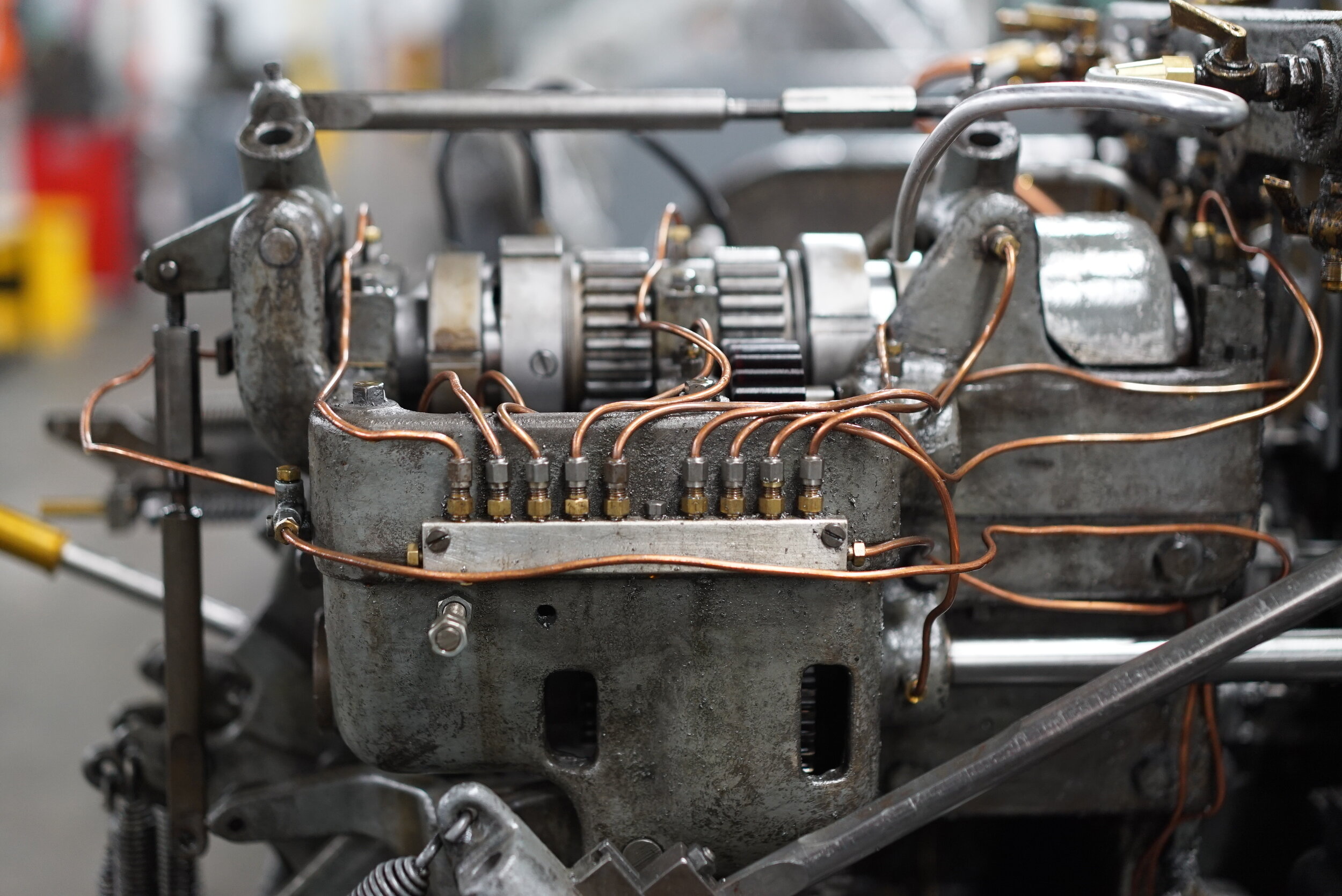

Multi spindle automatic screw machines have been around for awhile now. They are an automatic bar fed machine with the capabilities to run multiple bars at once with each position having different cutting tools operating in the cut at the same time. Having multiple tool positions in the cut at the same time improves on cycle time and ultimately saves on cost. Having multiple bars running at the same time allows us the ability to take on high volume production work such as fittings, fasteners and pins.

DAVENPORT SCREW MACHINE DePARTMENT: THE FIVE SPINDLE WORKHORSE

We operate 26 multi spindle Davenports out of our Oregon screw machine shop. Our 5-spindle Davenport screw machines are best suited for producing high volume parts under 3/4" in diameter. They can run run shapes such as hex and square as well as millimeter sizes which helps when selecting the nearest sized material for your parts.

Davenport screw machines are equipped with threading, countersinking, and 5th position burring attachments to name a few. These attachments are for turning components with distinct features such as external threads, internal threads, and axial holes. Over half our machines are equipped with spindle stopping capabilities which allows us the ability to stop a spindle and cross drill and cross tap parts. This eliminates the need for secondary machining processes.

These machines are geared towards high volume production runs of 20,000 pieces up to multi million pieces. We offer a stocking program and will ship parts out on releases. This helps us stay competitive by amortizing set up costs over a higher volume and getting better material prices due to purchasing more at once.

ACME-GRIDLEY Screw Machines & WICKMAN SCREW MACHINES

We also have two other multi spindle automatic screw machine departments. We have Wickman screw machines and Acme Gridley screw machines with bar diameters up to 2-5/8" capacity.

These Wickman screw machines and Acme screw machines have 6 spindles where the davenports only have 5. These machines also come with a heavier base and hold better tolerances on diameters of harder materials such as 304 stainless steel and 316 stainless steel. With the added spindle you get one more bars worth of parts on each stock up leading these machines to be our go to option for high volume production runs.

Tornos DePARTMENT: Swiss Multi Spindle

A Tornos Bechler machine is a type of Swiss-made automatic lathe, known for its precision in machining small, intricate parts. Originally designed for high-volume production in industries like electronics, and medical devices, these machines excel in producing complex components with tight tolerances. Tornos Bechler machines are valued for their reliability, efficiency, and the ability to perform multiple operations on a workpiece without needing to change tools or reorient the part, making them ideal for both traditional and modern manufacturing environments.