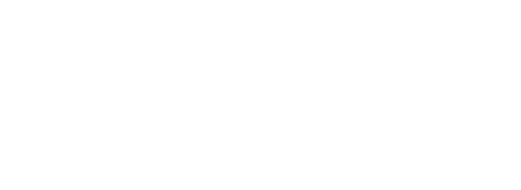

What is an automatic screw machine?

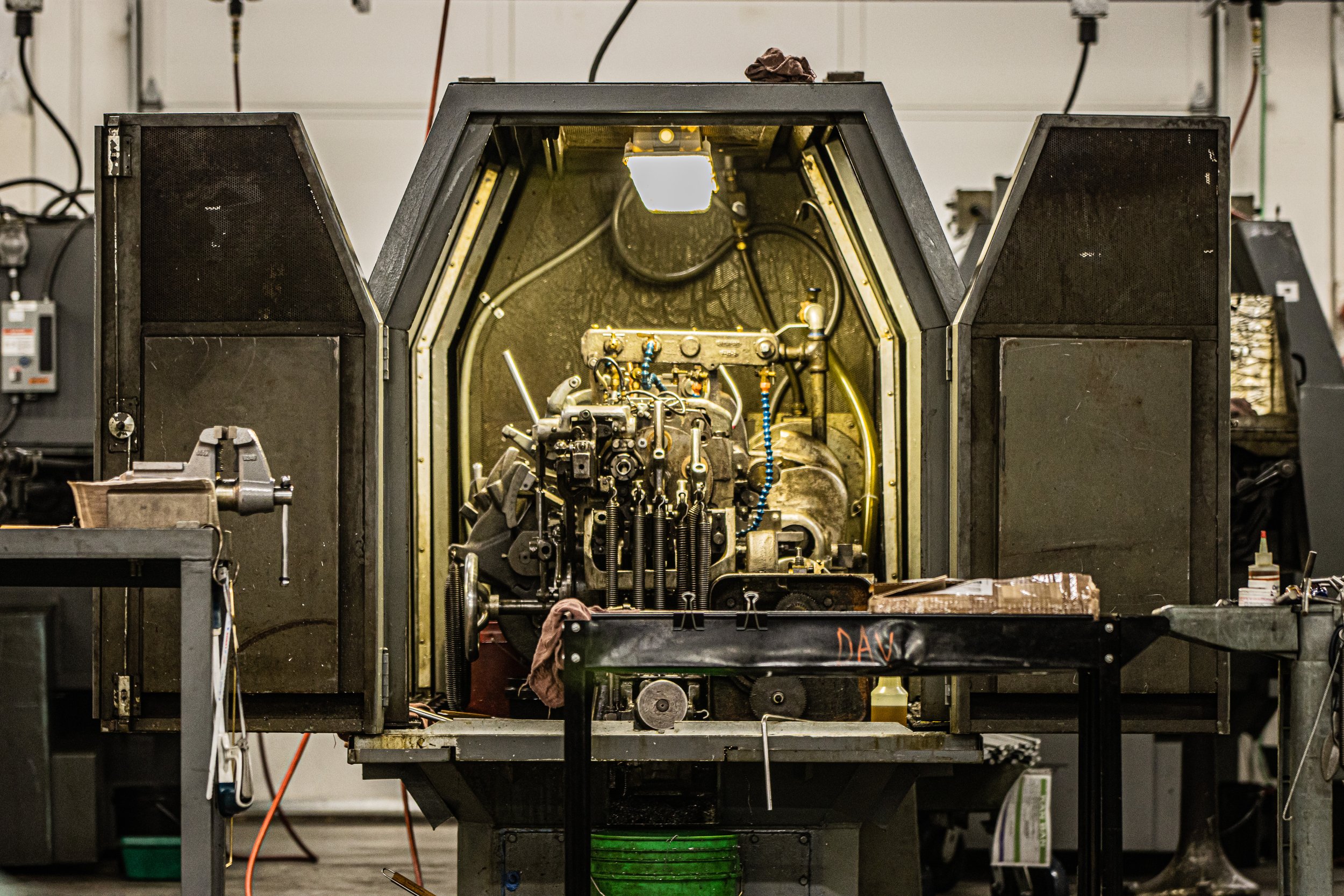

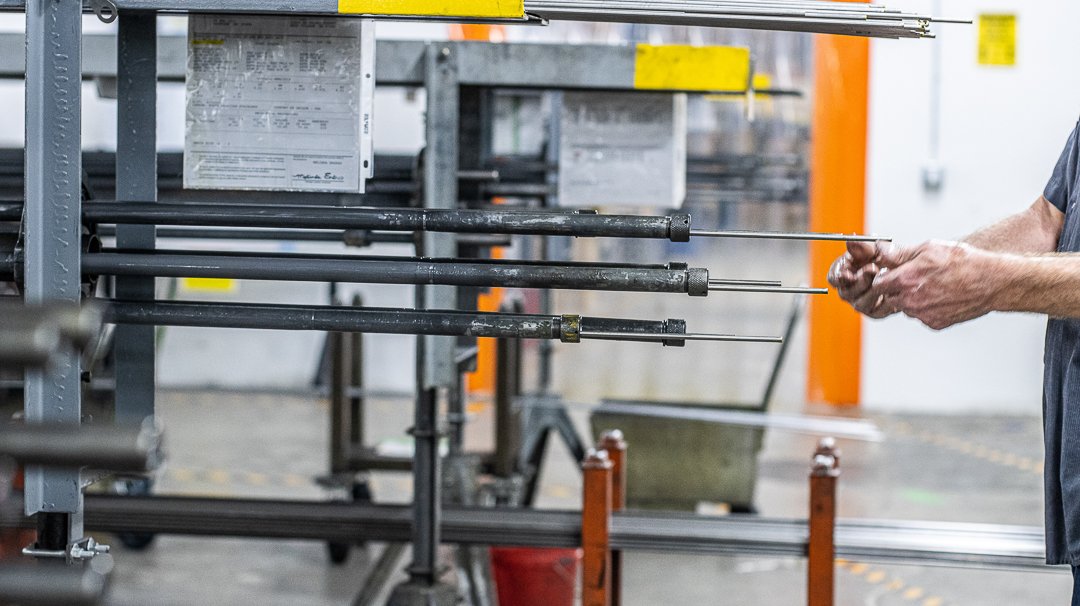

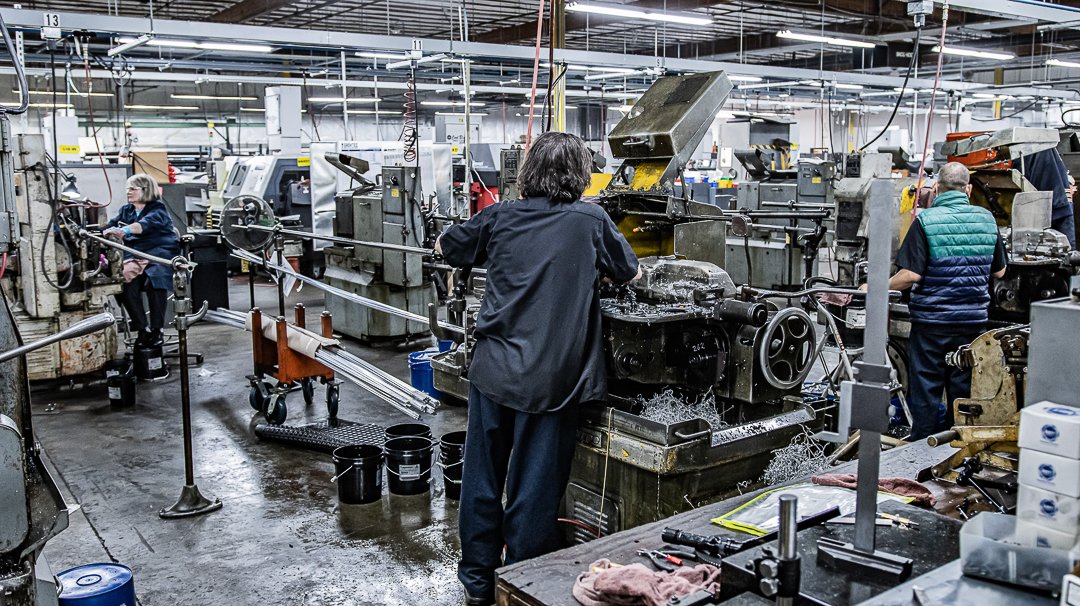

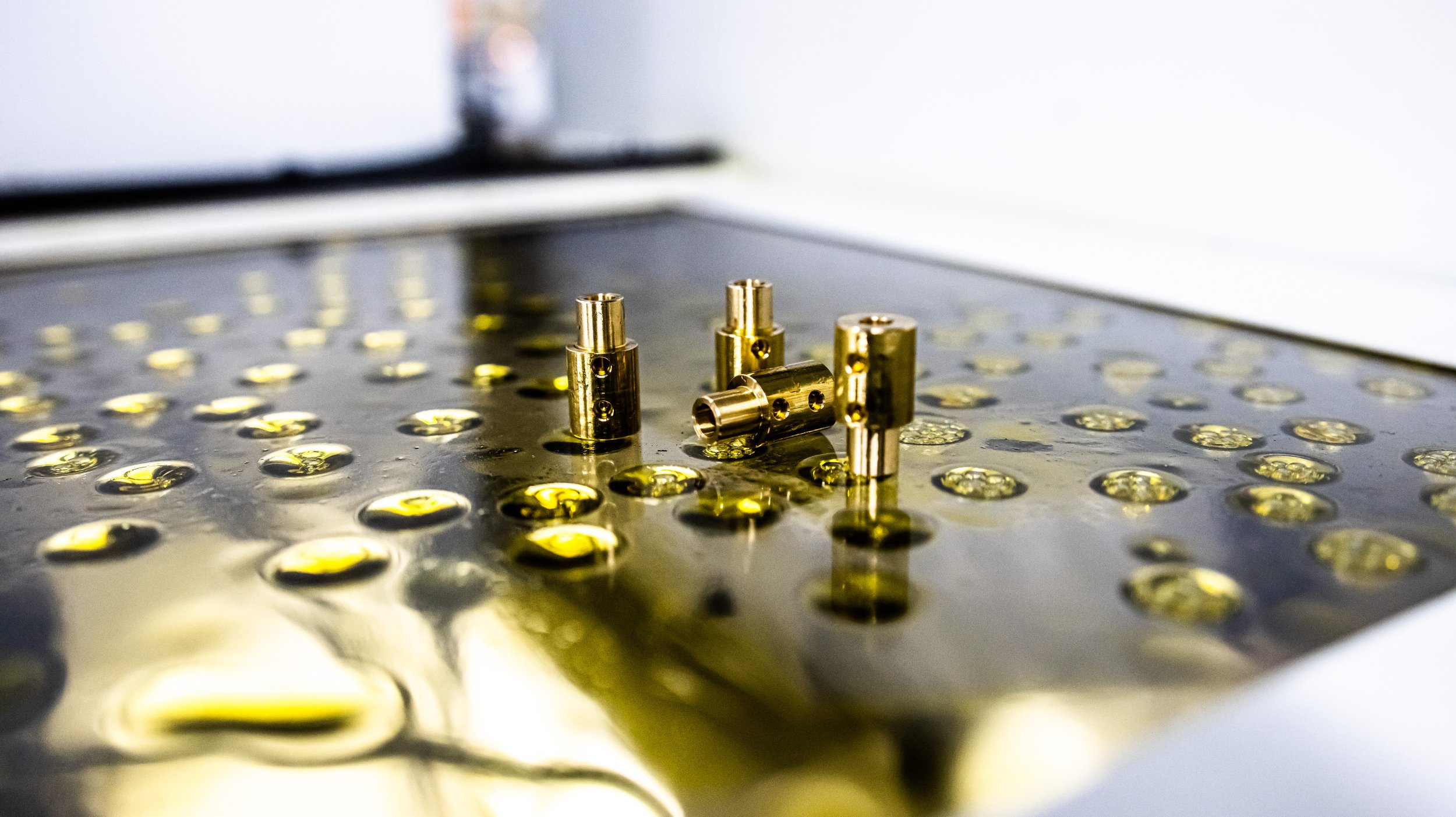

Automatic screw machines, the unsung heroes of the manufacturing world, play a crucial role in producing intricate, high-quality components with efficiency and precision. These versatile machines serve a wide range of industries, from automotive to aerospace, effortlessly turning out parts that keep our modern lives running smoothly. Their impressive capabilities stem from their ability to perform numerous functions, such as drilling, turning, and milling, all within a single, streamlined process. The next time you marvel at the complexity of your favorite gadget or the reliability of your trusty vehicle, remember the humble automatic screw machine that lent a helping hand in their creation.

“What different types of automatic screw machines are there?”

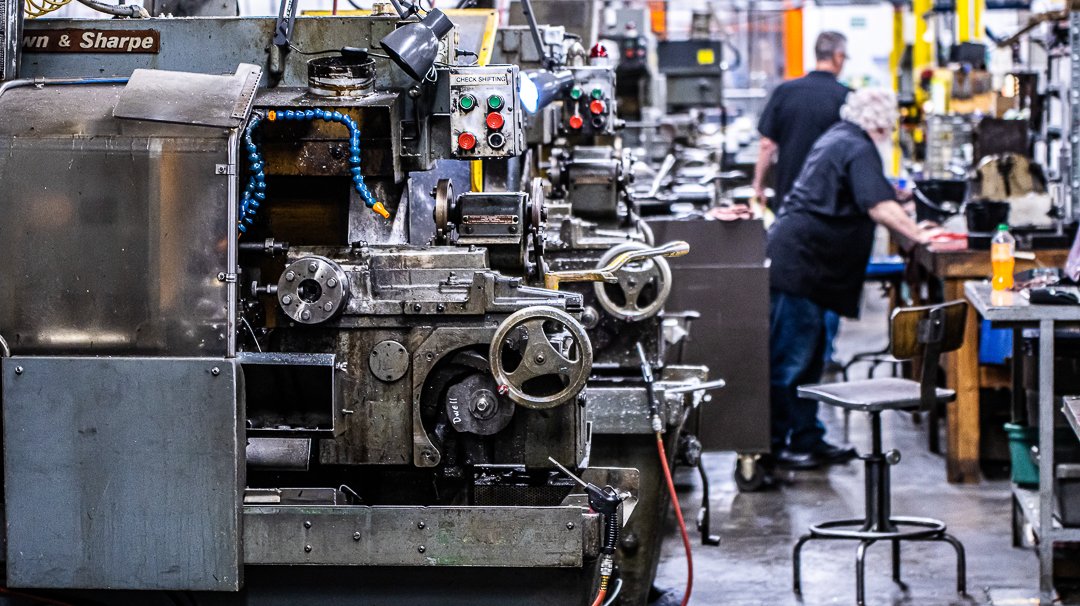

To better understand the versatility of automatic screw machines, let's explore the various types available in the market. Swiss-type screw machines are known for their precision and ability to produce small, intricate parts, making them ideal for the medical, aerospace, and electronics industries. On the other hand, turret-type screw machines offer more flexibility and can handle larger, more complex workpieces suited for the automotive, construction, and heavy machinery sectors. Finally, CNC (Computer Numerical Control) screw machines are capable of delivering both precision and flexibility, with advanced programming options and multi-axis capabilities that cater to a wide range of applications, further demonstrating the vast potential of automatic screw machines in the modern manufacturing landscape.

Brand names include: Acme Gridley, Browne & Sharpe, Citizen, Conomatic, Davenport, Glidemeister, Hardinge, Index, Miyano, New Britain, Star, Tornos, Traub

“Will automatic screw machines be around much longer?”

As advancements in technology continue to propel us forward, the future of automatic screw machining promises even greater innovation and capabilities. Developments in artificial intelligence, machine learning, and robotic automation will allow these machines to make smarter decisions and operate more efficiently, further enhancing the manufacturing process. Additionally, the growing demand for customized, intricate components in a variety of fields will drive machine manufacturers to seek innovative solutions and improvements to meet these needs. Ultimately, the evolving landscape of the manufacturing industry will rely on automatic screw machines to continue pushing boundaries and deliver exceptional quality in their output.